Imagine this: you take a wonderful bite of a french baguette and begin to wonder where it was made, how it was made, what kind of flour was used? And what about the extra ingredients? Going deeper: where did the wheat come from, the seeds, the soil, the fertilizer, the GHG emissions?

That baguette has already gone through so many stages to get to you even before you take a bite, digest it, and…well, process it.

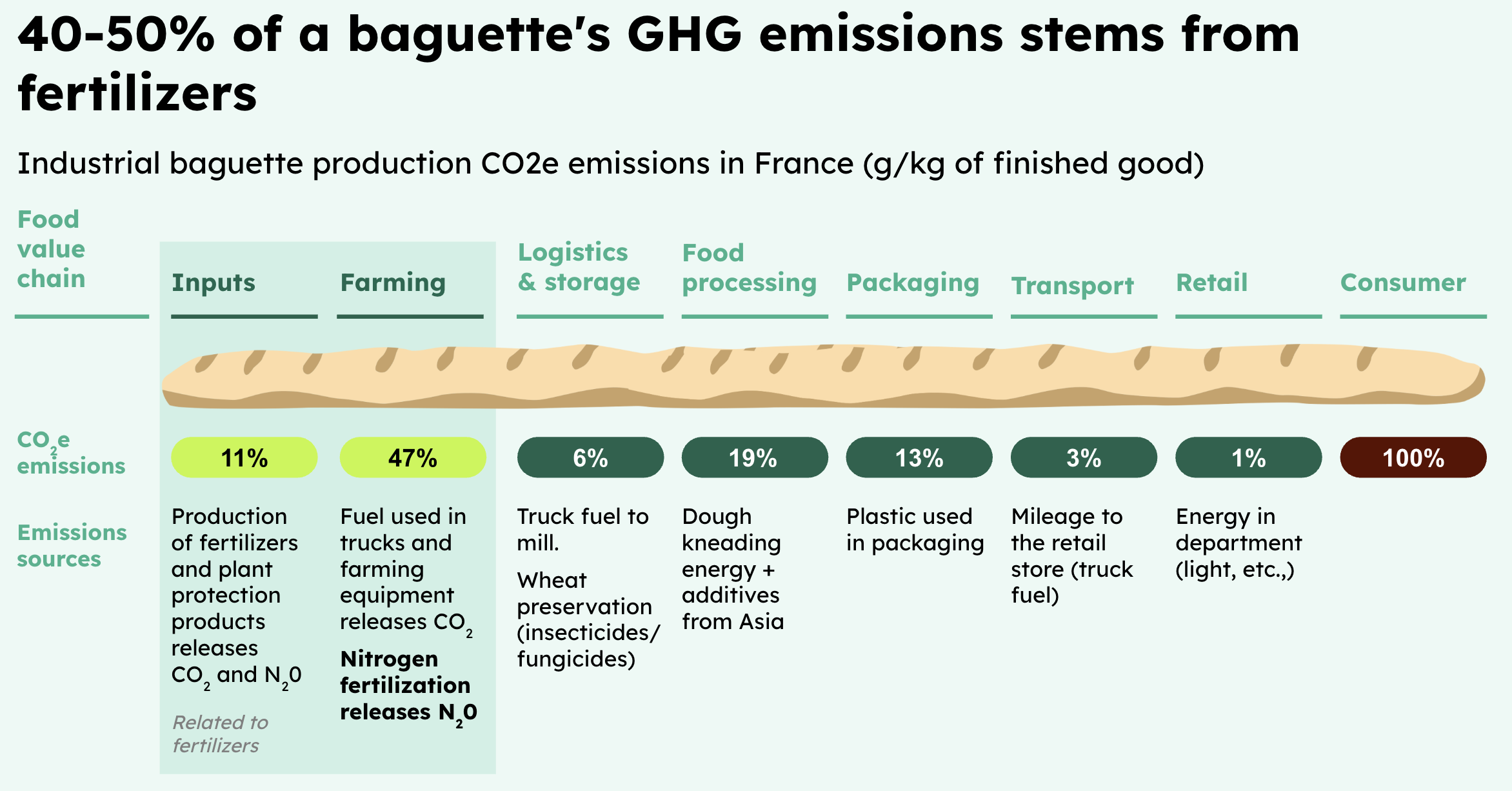

But - did you know that 40-50% of a baguette’s total GHG emission stems from fertilizers?

That’s why we call it your food’s hidden carbon footprint.

To make sense of this journey, our partners at Corporate Value Associates (CVA) visualized the full value chain, from inputs to the final loaf.

At the input stage, your wheat hasn’t even begun growing yet. The fertilizer, that will be used later, is being manufactured. The production of fertilizers and pesticides releases carbon dioxide and nitrous oxide - making up roughly 11% of the baguette’s footprint already.

At the farming stage, the wheat is now growing! However, the emissions at this stage are the heaviest. Fuel for trucks and farming equipment plays a role, but the major culprit is nitrous oxide, a greenhouse gas 273 times more potent than carbon dioxide, released from nitrogen fertilizers.

The next stages include logistics, storage, mill, processing and so on until it reaches the consumer - all overshadowed by the emissions from just the farming stage.

Focusing solely on fertilizers, there’s two key stages: emissions from fertilizer production and emissions from in field/usage. If we zero in on fertilizers alone, this is a split of 30% from production, 10% transport, and 60% from field/usage.

At the production level, the Haber-Bosch process, which synthesizes ammonia from nitrogen using natural gas, is heavily polluting, yet can be made cleaner using renewables. Focusing on green ammonia production, using green hydrogen (electrolysis powered by renewable energy) combined with nitrogen via Haber-Bosch but powered by wind, solar, or water, you will get green ammonia.

At the field level, different types of fertilizers are used depending on crop, soil, and many other factors. There are practical interventions available. For example, adding nitrogen stabilizers can reduce on field N₂O emissions by 30–70%. Controlled release fertilizers (CRF, fertilizers with a coating to release the nitrogen in a more controlled way) can see a reduction of 30-60% of on field emissions.

The good thing is that adding stabilizers is both cost effective and has a very significant impact on reducing emissions. In addition it does not require major practice changes from the farmer. So it's a very good candidate to start implementing. Especially supported by our science based protocols and insetting market mechanisms for proper claims across the supply chain.

Reduce 10% to 30% of your Scope 3 footprint instantly, at half the cost, with nitrogen stabilizers. Learn how insetting and nitrogen stabilizers are a match made in heaven and can help reduce the footprint of your food.